To the average person, rotor balancing is often a "black art". Most people’s knowledge of balancing is limited to car wheels and tyres that must be balanced before fitting to cars; otherwise they will experience steering wheel judder, uneven wear on tyres and so on. This article will give you an insight into the world of balancing and help to remove the "black art".

The unbalanced rotor is spoken if the main axis of the body's center of gravity is different from the main axis of its rotation. Expressed according to ISO 1940-1, the main axis of inertia does not match the axis of rotation. The axis of inertia is the axis around which the wheel can rotate without unbalance. Practically all newly machined parts are non symmetrical due to blow holes in castings, uneven number and position of bolt holes, parts fitted off-centre, machined diameters eccentric to the bearing locations etc.

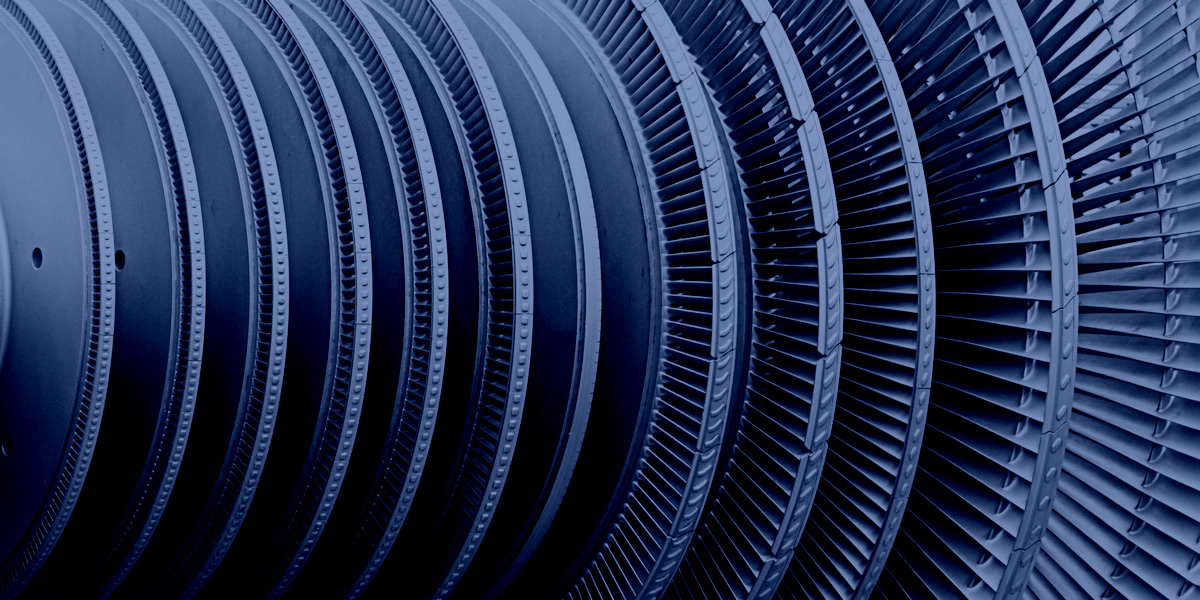

An unbalanced rotor, when rotating, wants to revolve around its mass centre axis. Because the bearings restrict this movement, the centrifugal force, due to the unbalance, causes the rotor to vibrate. This vibration causes wear to the bearings, creates unnecessary noise, and, in extreme cases disintegration of the rotor itself can be experienced. It is therefore necessary to reduce the unbalance to an acceptable limit.

Similar to machining tolerances, there are also balancing tolerances for which balancing is permissible. To determine the tolerance for residual imbalance of rotors, we use international standards, eg car wheels are balanced in the G40 grade, but small electrical fittings are balanced in grade G 2.5. The grades are converted to unbalance units, depending on the rotational speed of the rotor according to ISO 1940-1 Vibrations - Requirements for rotor balancing quality in constant (rigid) condition. Quality requirements for the rotor balancing in flexible state are given in ISO 11342.

The units of unbalance are mass times radius in which the center of gravity of the mass rotates about the axis of rotation. For example: a weight added to a certain position on the part being balanced would shift the axis the center of gravity (axis of inertia) towards the axis of revolving (rotation axis) and cause a balance. The weight of correction multiplied by the applied radius will give an unbalance unit. For metric measurement the units will be gram-millimetres (gmm) or for large rotors, gram-centimetres. The Imperial equivalent will be gram-inches or ounce-inches.

Rotors fall into two groups. One is where the rotor is rigid and does not deflect up to and including the operating speed.

The other group comprises flexible rotors that “bow” up to the operating speed. The first deflection seen is a “skipping rope effect” which means the centre of the rotor at speed moves out from its rotational axis, causing high “static” unbalance.

There are three types of unbalance:

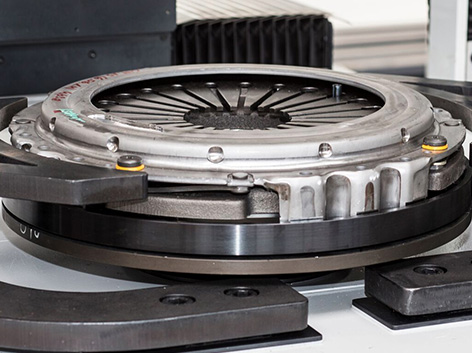

For the correction of the unbalace are used so-called balancing planes created for this purpose on the rotor by the designer. There are two ways to correct unbalance. By removing the material by drilling, milling, etc. Another solution is to add material, so-called balancing weights placed to groove, screws or welded mass so that the unbalance is reduced.

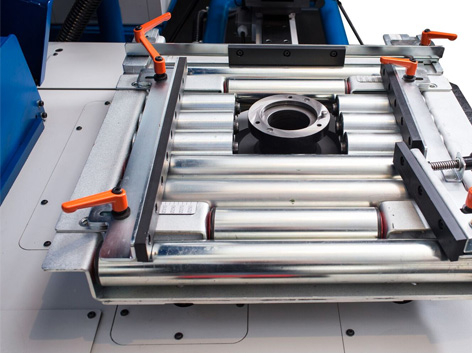

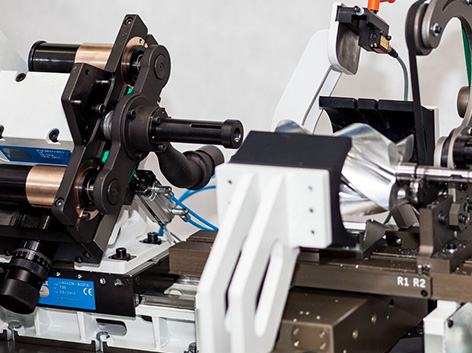

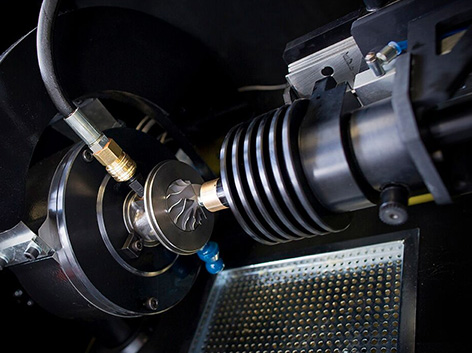

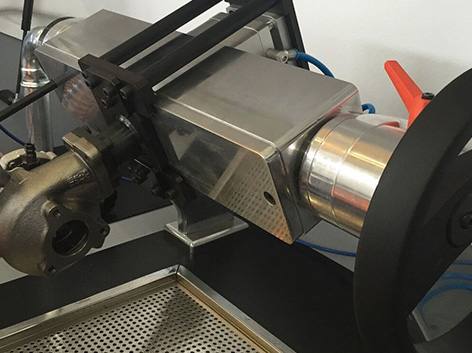

To identify the position and amount of unbalance, balancing machines are used by a rotor manufacture to correct any unbalance that exists. These machines are so sensitive that they can easily and accurately identify any mass axis 0.001mm off the running axis.

One type of machine will only identify static unbalance. This is used for balancing disk shaped parts. Another type of machine will identify unbalances in two axial planes, e.g. for balancing a rotors whose length is proportionally greater than its diameter. These machines are available in versions that balance the rotor in either the horizontal or vertical axis.

With the use of modern electronics, accuracy easily exceeds national and international standards. The set-up of the machine is very simple by just typing measurements into a computer.

Because unbalance exists in a component even when stationary, rigid rotors can be balanced at a low speed, just enough to produce a centrifugal force to register the unbalance.

This type of rotor is balanced at a low speed where the rotor does not flex. Correction for unbalance is made, then the speed is gradually increased, and the unbalance is corrected in stages until the rotor’s operating speed is reached.

With the high cost of replacing damaged rotors, the airline industry stipulates that parts or sections of rotors that are changed must maintain an acceptable balance. The technique involves using dummy adjacent parts, for example balancing a compressor module with a dummy turbine module and replacing compressor and turbine blades without any further balance. These techniques are available to general industry if customers require them.

The latest production methods reduce or eliminate the need for balancing in low speed applications, but with ever increasing speeds used on rotating machinery, dynamic balancing will be necessary for the foreseeable future. An understanding of dynamic balancing streamlines the complete production process.

Podnikatelská 565,

190 11 Praha 9 - Běchovice

Podnikatelská 565,

190 11 Praha 9 - Běchovice